Rolling out technology across multiple locations should be predictable.

In reality, nationwide rollouts are where even well-funded projects go sideways.

We’ve seen it repeatedly: budgets blown, schedules missed, store openings delayed, executives frustrated, and internal IT teams left holding the bag. The problem usually isn’t the technology—it’s execution.

Here’s why nationwide rollouts fail, and more importantly, how to avoid the most common (and expensive) mistakes.

1. The Plan Looks Good—Until It Hits the Field

Most nationwide rollouts start with a solid plan created at headquarters. Network diagrams are approved. Equipment is spec’d. Timelines are established.

Then the project reaches Site #1.

Suddenly:

- The MDF isn’t where the drawings say it is

- Conduit is blocked or non-existent

- Ceiling types vary wildly by location

- Power is insufficient or undocumented

- Local building codes aren’t consistent

What looked clean on paper becomes chaos in the field.

How to avoid it:

Every successful rollout begins with real site surveys, not assumptions. That means boots on the ground, photos, measurements, and validation—before equipment ships or installers are dispatched.

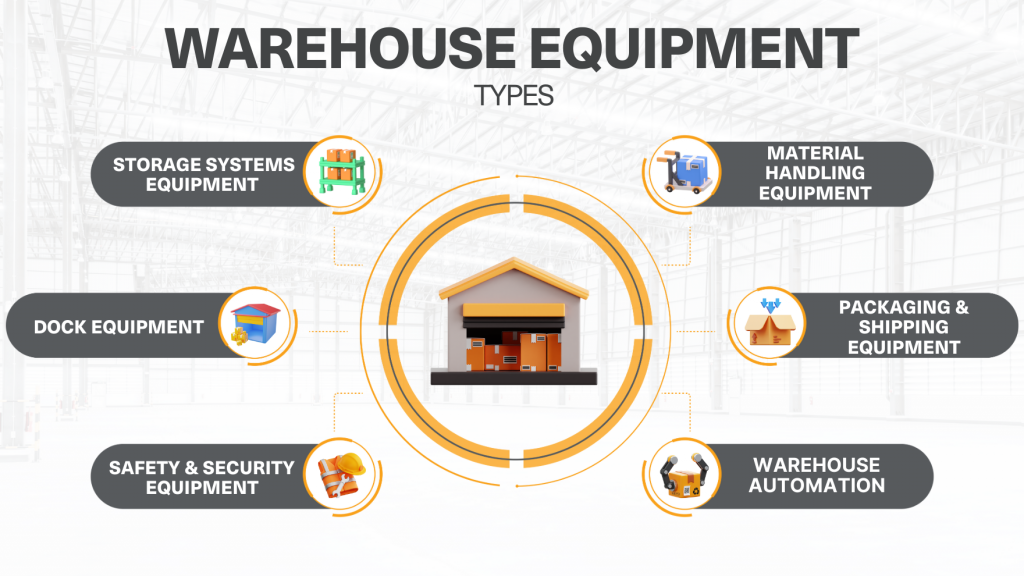

2. Too Many Vendors, No True Owner

A common failure point is fragmented responsibility:

- One vendor handles cabling

- Another ships equipment

- Another provisions circuits

- Another installs phones or switches

When something goes wrong, everyone points somewhere else.

Without a single accountable rollout partner, coordination collapses.

How to avoid it:

Assign one primary rollout owner responsible for coordination, escalation, documentation, and sign-off across all locations. Subcontractors can exist—but accountability must be centralized.

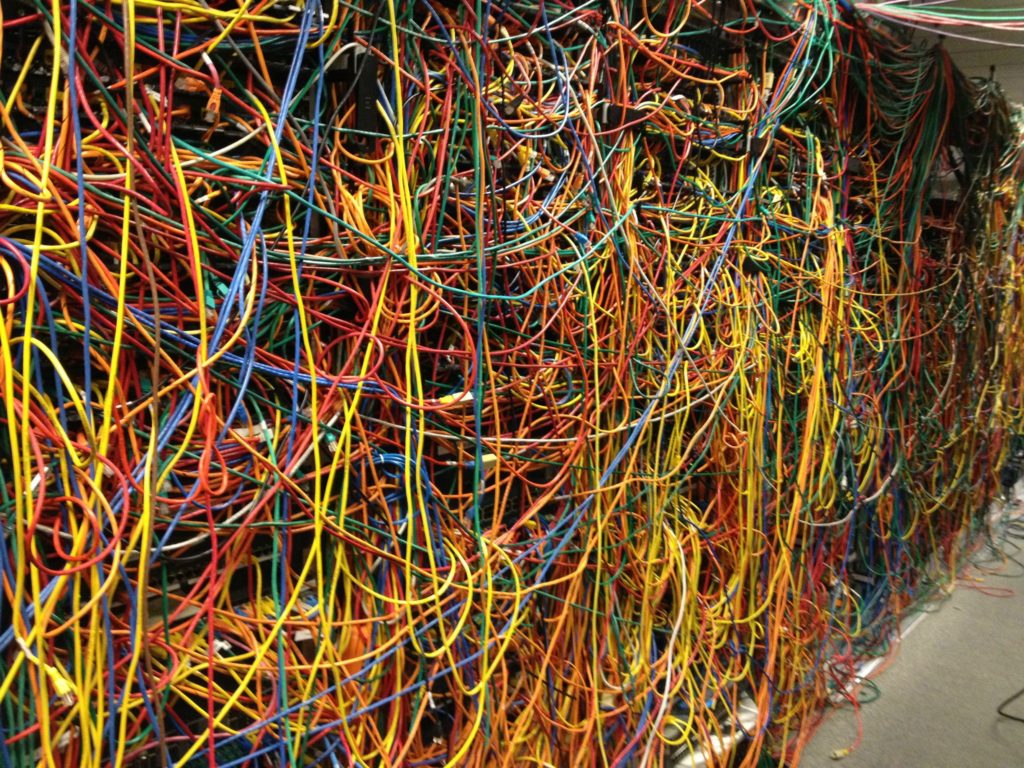

3. Inconsistent Installers = Inconsistent Results

Nationwide rollouts often rely on regional installers with varying skill levels, standards, and documentation habits.

That’s how you end up with:

- Labeling that doesn’t match diagrams

- Racks mounted differently at every site

- Inconsistent patching and grounding

- No usable as-built documentation

This becomes a long-term operational nightmare for IT teams.

How to avoid it:

Use standardized install guidelines, checklists, labeling schemes, and photo requirements across every location. Field work should be audited, not assumed.

4. No Real Change Control Process

Nationwide projects will encounter surprises. The problem isn’t change—it’s unmanaged change.

We frequently see:

- Field changes made without approval

- Additional labor added without documentation

- Scope creep justified verbally

- Finance surprised at the final invoice

This erodes trust and kills budgets.

How to avoid it:

Enforce a formal change control process:

- Written scope changes

- Pre-approved cost deltas

- Documented field conditions

- Clear sign-off authority

If it isn’t documented, it doesn’t happen.

5. Poor Communication Between Stakeholders

In failing rollouts, information lives in silos:

- Facilities doesn’t talk to IT

- IT doesn’t talk to vendors

- Vendors don’t talk to each other

- Executives get updates too late

By the time issues surface, it’s already a crisis.

How to avoid it:

Successful rollouts run on structured communication:

- Centralized ticketing or project tracking

- Weekly status reports

- Clear escalation paths

- Shared documentation repositories

Everyone should know where the project stands—at all times.

6. Underestimating Logistics and Timing

Shipping equipment to dozens (or hundreds) of sites is not trivial.

Failures often include:

- Equipment arriving before sites are ready

- Equipment arriving after installers leave

- Missing components halting installs

- Storage issues at retail locations

Each delay compounds across locations.

How to avoid it:

Tie logistics to validated site readiness. Equipment should ship only when sites are confirmed ready, and delivery windows must align with scheduled labor.

7. No Post-Install Validation

Many rollouts end the moment the installer leaves.

That’s when problems begin:

- Ports aren’t tested

- Devices aren’t reachable

- Labeling doesn’t match documentation

- IT inherits undocumented environments

How to avoid it:

Require post-install validation:

- Port testing results

- Photo documentation

- As-built diagrams

- Sign-off checklists

A rollout isn’t complete until it’s verifiable.

What Successful Nationwide Rollouts Have in Common

Across hundreds of multi-site projects, successful rollouts consistently include:

- Pre-deployment site surveys

- Centralized project ownership

- Standardized installation practices

- Disciplined change control

- Clear communication

- Coordinated logistics

- Documented close-out

Technology doesn’t fail—process does.

How DataTel 360 Helps Prevent Rollout Failures

At DataTel 360, nationwide rollouts are a core part of what we do.

We support:

- Structured cabling & fiber deployments

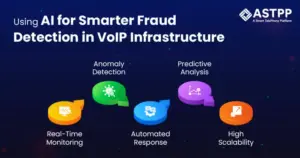

- Network & Wi-Fi rollouts

- Cloud VoIP and UC deployments

- Retail, multi-site, and enterprise locations

- Smart hands and field engineering nationwide

Our approach is built around planning, validation, and accountability—not guesswork.

👉 Learn more about our Nationwide Rollout & Onsite Services

Ready to Do Your Next Rollout the Right Way?

If you’re planning a multi-location deployment—or cleaning up one that’s already gone sideways—now is the time to get expert help.

✔ Avoid delays

✔ Control costs

✔ Standardize results nationwide

📞 Contact DataTel 360 today to schedule a rollout consultation or site survey.